There have been so many tools and machines invented to make people’s lives easier and so much better. The hydraulic pump and vacuum pump are a few examples. Another brilliant invention has also been achieved in conveyor belt cleaners. Cleaning and sanitizing conveyor belts can be complicated. However, a good conveyor belt cleaner can anitizes, cleans and dries conveyor belts without the use of chemicals. It uses a breakthrough industrial solution system that involves a portable sanitizing system and deep steam cleaning for conveyors even during production. It leaves conveyor belts free from contaminants and microorganisms. It is a 100 % organic, completely green technology.

Conveyor Belt Cleaning System Features

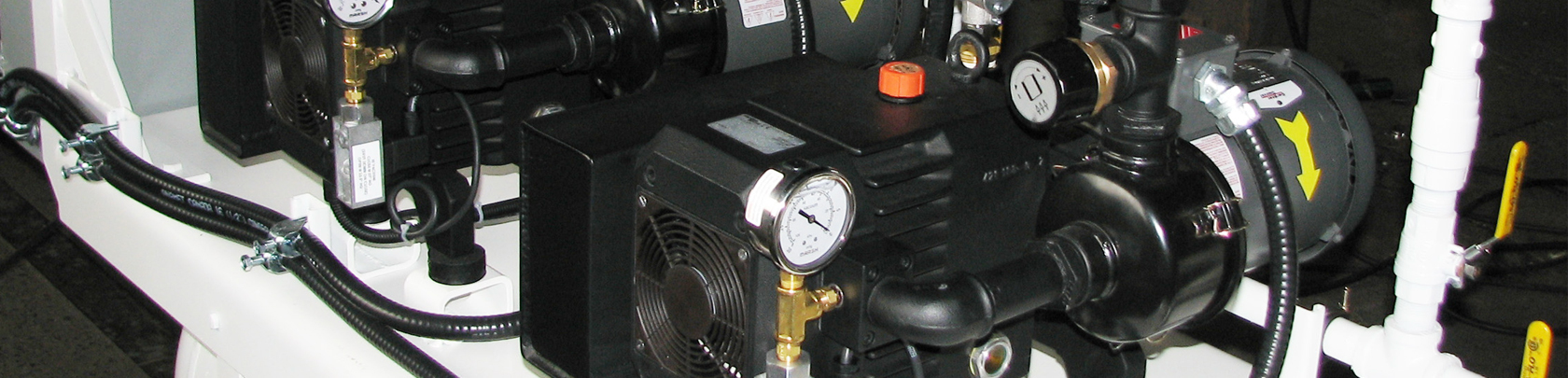

This conveyor belt cleaner is easier to use and much faster than the traditional conveyor belt cleaning systems. It also works efficiently on most conveyor styles and sizes. And, since it’s easy to install, the cleaning process is quick and easy. It is designed to give 24/7 sanitizing and cleaning power and cut water use by producing 94% of dry stream, which requires only 15 liters of water per hour. The heat it produces is enough to release soils and kill germs instantly. The Conveyor Belt Cleaning System uses a electronic control box to regulate the steam, and it can be mounted on the steam generator or the conveyor.

How It Works

Who would have thought that sanitizing can be possible in a responsible and environmentally friendly way? With only 15 liters or water per hour, heated under pressure to maximum temperature until it turns to dry steam vapor, the conveyor belt cleaner becomes a very powerful cleaning machine. In fact, this is the only technology out there, that can powerfully penetrate a stainless steel’s micropores. Dry steam vapor particles penetrate all cracks and crevices to remove stubborn dirt, grease, and kill bacteria and microorganisms at once. This cleaning system leaves belt conveyors clean, sanitized and dry while they are operating or not. What’s more is that, it is a patented technology that cleans meshes, metals, plastics, or flat industrial conveyor belts, such as pharmaceuticals and food processing.

Conveyor belts used for these purposes require hygienic cleaning. In conclusion, the Conveyor Belt Cleaning System has several major advantages. It cleans and sanitizes in an organic way, without using harmful chemicals. It also saves costs on water usage and prevents loss of profit from labor shutdown since it can clean the conveyor belt even while it’s running.