Have you ever paid attention to the importance of hydraulic cylinders in modern day construction? Every single tube you find on or under a machines arm while staring at a building in process is most likely one of these. As you may have guessed by the description given before, they are what power these arms in a unidirectional stroke in order to move or lift something which requires a lot of force.

The Power Itself

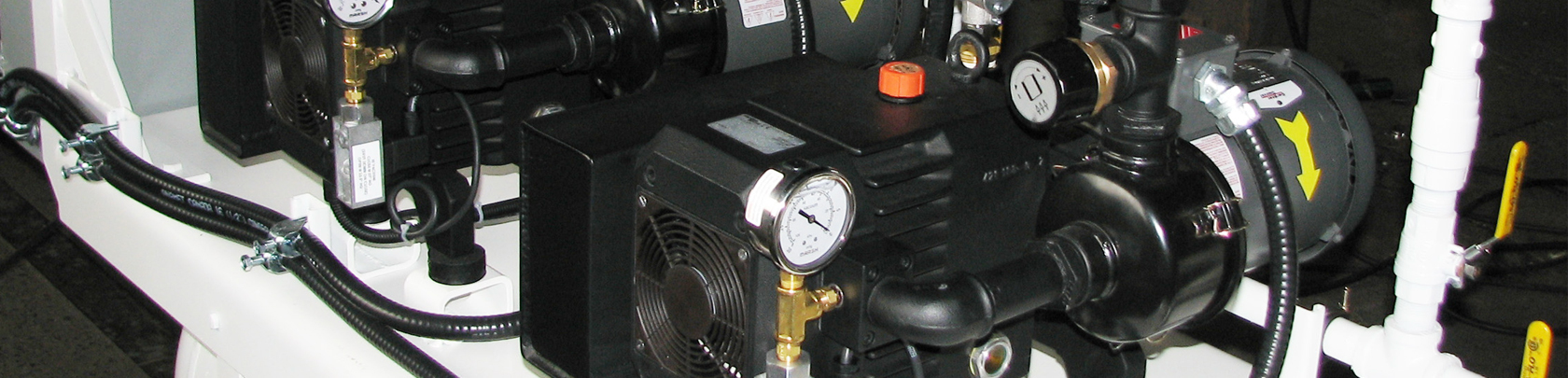

A hydraulic cylinder is made up of many parts like barrels and pistons, but mainly the force will come from a pressurized hydraulic fluid which tends to be oil. Inside the cylinder, this fluid’s flow is regulated by a pump which will in turn generate a pull force.

You will also find that there are two types of cylinders: Single acting and double acting.

- The first ones are simpler in design and generally cheaper. The oil enters through a port at one end of the cylinder, extending the rod which later gravity will send back into the piston.

- Double acting cylinders, on the other hand, have a port at each end and require the fluid to flow in or out of both sides for both movements (extension and retraction).

Different Designs

In the industry of hydraulic cylinders you will find many designs available:

- Welded Body: it doesn’t have a tie rod and the barrel is welded directly into the end of the caps as well as the ports.

- Tie Rod: mostly seen in industrial factory applications, these hold the end caps using threaded steel rods.

- Compact: utilized when the mounting space is expensive or difficult to acquire and the application demands a high force.

- Telescopic: also called multi stage rod, due to the fact that it is actually a succession of rods tied together for force or distance required

Which One Should You Buy?

As you can see, there are many kinds of hydraulic cylinders in the market so the best thing to do is actually to ask for a professional’s help to suit your manufacturing or building needs. That way you’ll find the proper tool for the proper task.