In the first part of this extended article, we talked about how to extend the life expectancy of your gas springs — and here, we continue that conversation. Let’s get right back into it.

Things to Avoid

To keep your gas springs working better, longer, never use the bottom of the spring as the strike surface — the top of the piston rod is the correct option. Rather than using improper or inadequate guidance, which can lead to side loading due to axial misalignment, us guide retainer sets, roller bearings, wear plates, and a hardened strike surface. That will extend spring life as well. Anything more than a single degree of side load on the piston rod is asking for a gas spring that fails years earlier than it could.

Along that same vein, avoid contaminants. Even minor contamination within a die can cause premature failure. Die designers ought to specify drainage holes in the spring pockets so that fluid doesn’t pool around the springs. Gas springs shouldn’t be exposed to caustic draw-die compounds or other contaminants; if your production line makes this a necessity, contact the gas spring’s manufacturer to talk about what protective measures you can take.

Preventative Maintenance

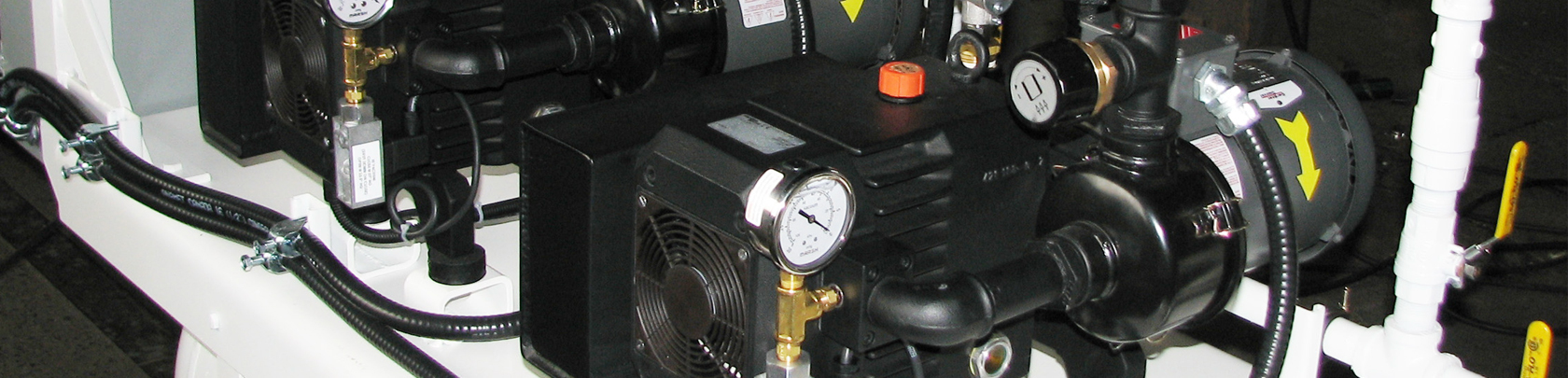

Of course, any discussion of extending the functional lifespan of any piece of equipment, from gas springs to pneumatic cylinders, needs to touch on the cornerstone of equipment care: preventative maintenance. Sound preventative maintenance procedures require users to check the pressure, temperature, and physical condition of the springs for signs of wear.

If a random sample of springs in a die exhibit signs of being overworked, overpressured, or overheated, every other spring should be examined as well. A significant variation in spring pressure or condition could indicate a flaw in the die’s design, build, or operation. If a specific spring’s pressure is low, check for leaks, then recharge and check for leaks again.

The physical condition of a spring should be determined with a visual examination; there should be no need to dismantle the spring. Worn springs that are still viable should be rebuilt. If the rod is damaged, it obviously will need to be replaced as well.

Following these four major areas of care should help any project keep its gas springs lasting as long as their construction allows — good luck!