The number one determinant of the life expectancy of a gas spring is, perhaps without much surprise, the manufacturer. Choosing a manufacturer whose representatives will offer you assistance choosing the best design for your job — and then actually listening to the reps — is a great step toward a long-lasting gas spring. Also, talking to your supplier about performance guidelines — specifically, operating temperature, speed, and charging pressure — can help you understand how to stay within a spring’s operating parameters, which will help it last.

The decision of which gas spring to use should be based on several criteria. The spring must match the task it’s intended for, it’s location in the die, and the mounting method most appropriate for the task.

Tool Build and Die Design

Die design is one of the most important parts of optimizing gas spring life. Such springs have standard operating specifications — for example, a spring may be charged to a maximum pressure of 150 bar (2175 psi), and reach a maximum operating temperature of 160 degrees Fahrenheit. Exceeding either of those guidelines will rapidly slash the life expectancy of that spring.

Futhermore, unless there is no other option, you should never use more than 90% of the stroke of a gas spring — and a rod travel of 75% to 80% is even better, as it reduced both in-cylinder pressure rise and the amount of heat produced per stroke. Further, aiming to distribute loads evenly between springs so that no one spring outworks the others and none are approaching full capacity goes a long way toward keeping a spring functioning in the long term.

Accessorizing for Lifespan

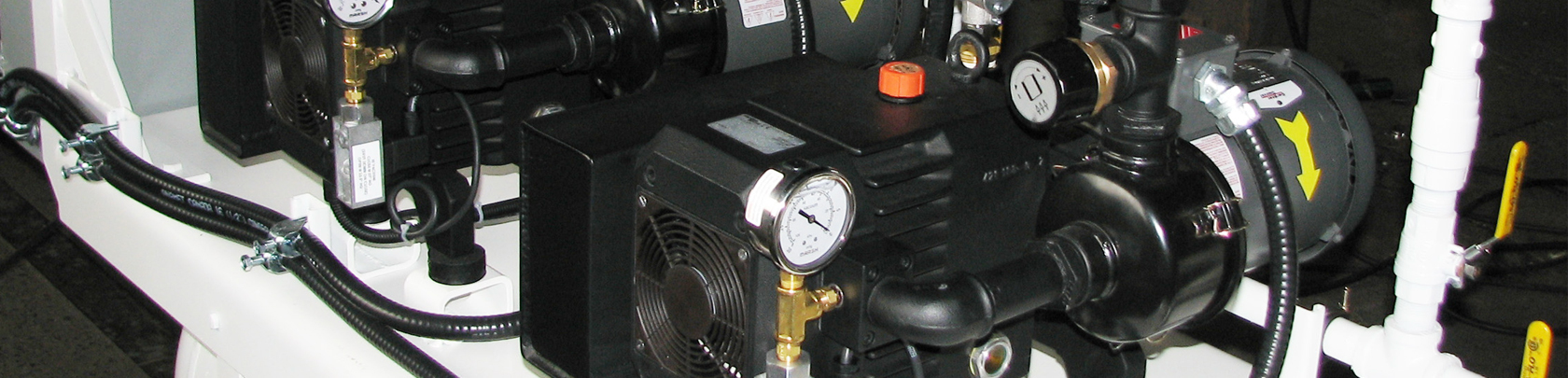

Gas spring accessories like nitrogen-gas surge tanks added to a piped system will add volume so as to maintain a lower pressure rise. Piping gas springs together with pneumatic fittings can give you the ability to monitor and control force from outside the die, giving you the ability to manually modify a spring’s operations based on external conditions like load, which further enhances the lifespan.

This is still only scratching the surface — come back next week for part II of our guide to maximize gas spring lifespan.