Hydraulic cylinders are used in large- and small-scale industry, from hand-held manual tools to massive construction vehicles and robots. A hydraulic cylinder provides the force that moves hydraulic fluid through its pipes, valves, and manifolds, where on the other end, it eventually reaches another cylinder that translates the movement of the hydraulic fluid into the movement of machinery. Hydraulic cylinders can be found in cars, cranes, oil rigs, bulldozers, draw bridges, and even in professional-grade long-reach pruning shears.

The primary components of a hydraulic cylinder are the cylinder, the piston head, and the piston rod. Mechanically, they work together much like a syringe — the piston rod pushes the piston head, which forms an airtight seal with the cylinder. The piston head forces the hydraulic fluid through the hole at the end of the cylinder. Because fluid cannot be compressed, and the entire sequence of pipes, valves, and manifolds is already full of fluid, any motion by the cylinder on one of the hydraulic series affects the cylinder on the opposite side without any delay.

Generally, the piston arm is powered by an electric motor, though there are plenty of exceptions. The outside of the cylinder and the piston arm are often painted with chrome for aesthetic purposes, but the inside of the cylinder and the piston head are under constant stress (as the hydraulic fluid pushes out equally on all surfaces of it’s container), so painting them would be counterproductive.

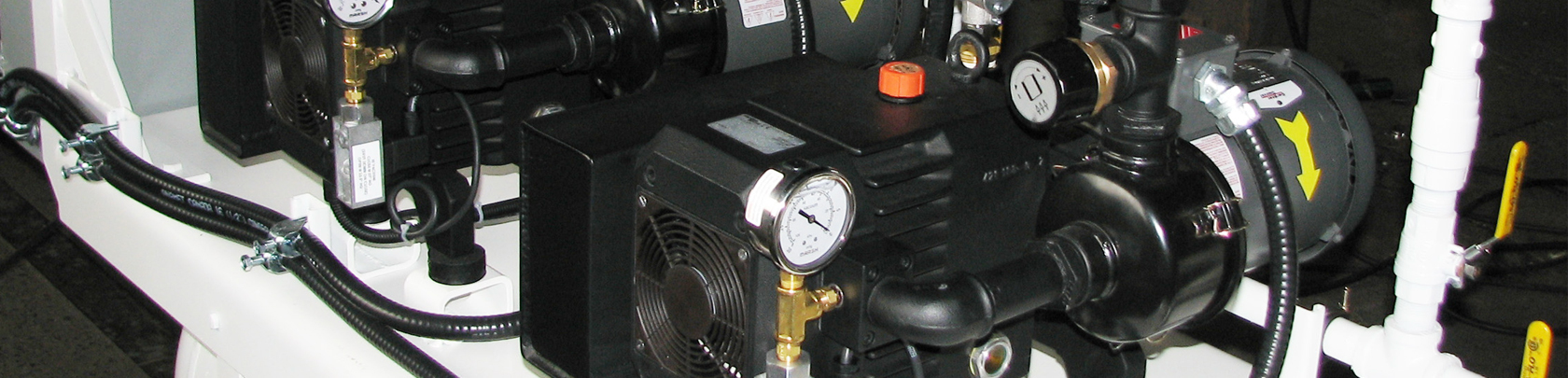

Cylinders come in several varieties. There are hundreds of different bores of cylinder available. They come in single-stage and double-stage (depending on whether you expect the force to some exclusively from one side or you need both sides to be able to move the other.) Cylinders are generally attached to reservoirs that contain additional hydraulic fluid and filters that keep the fluid free of impurities.

Quite often, a single powerful cylinder is used to power a variety of different motions within the same machine. In that case, a hydraulic manifold that can ‘switch’ one cylinder between several different endpoints is put into play. For any machine that only needs to make one motion at a time, a single hydraulic cylinder operating on a manifold makes for a lower cost of ownership over time.