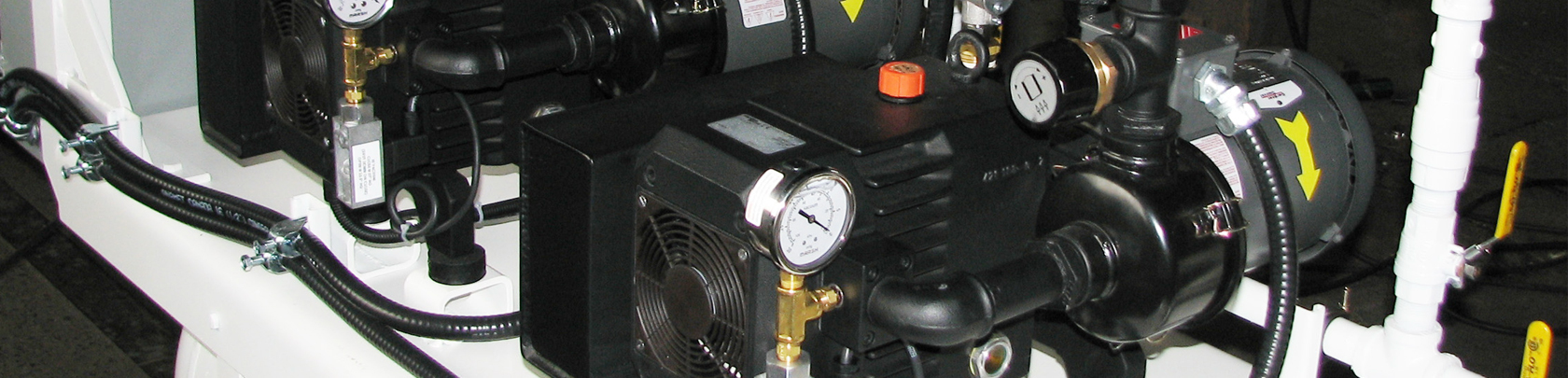

Centralized pneumatic air tools (not to be confused with Central Pneumatic, a brand name) offer quite a bit in terms of pricing, variety, durability, and efficiency. The concept behind central pneumatic is simple: you acquire a single, powerful pneumatic pump that sits quietly in one corner of your facility. Long, airtight pneumatic lines extend from that central pump out to wherever the work needs to be done; on the far end, those lines connect to a wide variety of possible tools with pneumatic fittings.

Price

The big advantage of having a central pneumatic system is that the individual tools that you attach to the end of each pneumatic line are significantly less expensive than the same tools that work using a battery or other ‘on-board’ power supply. As long as you maintain and upkeep the central pneumatic unit properly, it will last for decades under normal circumstances. Between the long-lasting central unit and the inexpensive end-tools, a central system can save you a lot of money.

Flexibility

Similarly, the ability to power virtually any tool that uses a pneumatic fitting means that as your needs change or one-off situations crop up, you can always just go get the tool you need for the job. If it’s a one-time thing, you can generally find a place to rent a tool — if it’s something you’ll need again soon, buying is naturally the better option.

Durability

When properly maintained, a central pneumatic pump can function with minimal trouble for dozens of years, even in a high-particulate environment like many industrial settings. Depending on the quality of the tools you purchase, you can find tools that are cheap and need frequent replacement, or that are quite costly and will also last for decades. Which is the better choice for your business model is up to you.

Efficiency

Because all of your pneumatic power comes from a single source, but the end points are several, you gain efficiency. Specifically, you gain cost efficiency because you don’t have to replace the entire pneumatic system when an individual tool breaks. It’s much more common for a tool, which takes beatings and gets handled daily, to break down compared to the central unit that sits in the corner pushing air day after day.